High-risk work environments place workers at constant exposure to falls, drops, and sudden load forces. Construction sites, industrial plants, and infrastructure projects demand dependable connection points between workers and safety systems. Yet, many incidents occur because connectors fail, are mismatched, or are incorrectly selected.

When connectors fail, the result is not only injury. Downtime increases, audits fail, and legal action follows. Compliance teams face pressure, while project timelines suffer. Safety officers must then answer questions that could have been avoided with correct equipment selection.

Safety Gear Connectors form the physical link between workers and fall protection systems. Indian Inovatix designs and supplies Safety Gear Connectors built for real site conditions, certified use, and long service life. This guide explains how Safety Gear Connectors improve protection in high-risk work environments and how to select them correctly.

What Are Safety Gear Connectors

Safety Gear Connectors are mechanical connection components used to join safety equipment within fall protection systems. They connect harnesses, lanyards, lifelines, anchors, and rescue systems into a continuous safety chain.

In high-risk work environments, connectors must hold dynamic loads during falls, sudden movement, and rescue operations. A connector is not an accessory. It is a load-bearing safety component.

Common forms of Safety Gear Connectors include:

- Carabiners

- Snap hooks

- Screw gate connectors

- Rebar hooks

- Anchorage connectors

Each connector serves a defined function within industrial safety systems.

Why Safety Gear Connectors Matter in High-Risk Work Environments

High-risk work environments involve working at height, confined spaces, sharp edges, moving machinery, and structural steel. In these conditions, Safety Gear Connectors perform three critical functions.

First, they maintain continuous attachment between the worker and the safety system. Second, they transfer fall forces safely through the system. Third, they prevent accidental disengagement during movement.

Failures often occur due to:

- Use of uncertified connectors

- Incorrect load rating

- Improper gate design

- Corrosion or material fatigue

Indian Inovatix designs Safety Gear Connectors with controlled gate strength, tested locking mechanisms, and material selection suitable for industrial use.

Types of Safety Gear Connectors Used in Industry

Safety Gear Connectors are selected based on task, environment, and system design. Each type has a specific application.

Carabiner Safety Gear Connectors

Carabiners are widely used for general attachment points. Industrial carabiners differ from recreational types in load rating and gate strength.

Industrial carabiner Safety Gear Connectors are used in:

- Vertical lifeline systems

- Horizontal lifeline systems

- Temporary anchorage setups

Indian Inovatix manufactures carabiners tested for industrial fall arrest loads.

Snap Hook Safety Gear Connectors

Snap hooks allow fast attachment to anchor points. They are commonly used in lanyards and twin leg systems.

Key features include:

- Self-closing gate

- Locking mechanism

- Load-tested body

Snap hook Safety Gear Connectors are selected where repeated connection and disconnection occurs.

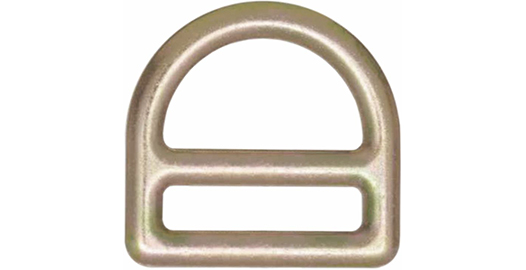

Rebar Hook Safety Gear Connectors

Rebar hooks are used in construction and steel erection. Their large opening allows attachment to beams and pipes.

These Safety Gear Connectors are critical in:

- PEB structures

- Infrastructure projects

- Bridge construction

Indian Inovatix supplies rebar hook connectors with controlled gate closure and tested load values.

Anchorage Safety Gear Connectors

Anchorage connectors form the connection between structure and fall protection system. These include beam clamps, slings, and fixed anchors.

They support:

- Permanent systems

- Temporary access work

- Maintenance tasks

Correct anchorage connector selection defines system safety.

How Safety Gear Connectors Improve Worker Protection

Safety Gear Connectors improve protection by maintaining system strength under stress. During a fall, force travels from harness to connector to anchor. Any weak point leads to failure.

Properly designed Safety Gear Connectors:

- Maintain gate closure during shock loading

- Distribute forces evenly

- Prevent roll-out and accidental release

Indian Inovatix tests connectors for dynamic loading, corrosion resistance, and repeated use cycles. This ensures consistent field performance.

Standards and Compliance for Safety Gear Connectors

Safety Gear Connectors used in industrial environments must meet national and international standards.

Common standards include:

- EN 362 for connectors

- IS standards for industrial PPE

- CE marking for regulated markets

Compliance ensures connectors perform as tested. Non-certified products often fail during audits and site inspections.

Indian Inovatix supplies Safety Gear Connectors with documented compliance and test records, supporting safety officers during inspections.

Selecting Safety Gear Connectors for Industrial Projects

Selecting Safety Gear Connectors requires assessment of task, environment, and system design.

Key selection factors include:

- Load rating suitable for fall arrest

- Gate type and locking method

- Compatibility with harness and lanyard

- Resistance to corrosion and wear

For EPC contractors and consultants, selecting connectors early during system planning reduces later changes and site risks.

Indian Inovatix supports bulk project requirements with consistent specifications across orders.

Safety Gear Connectors in Construction and Infrastructure Projects

Construction and infrastructure sites expose connectors to dust, weather, sharp edges, and heavy handling.

Safety Gear Connectors used here must support:

- Frequent movement

- Structural steel attachment

- Variable anchor geometry

Indian Inovatix supplies Safety Gear Connectors used in:

- Metro rail projects

- Highway structures

- Industrial sheds and PEB sites

Each connector is designed for repeated site use without performance drop.

Safety Gear Connectors for Confined Space Work

Confined spaces require reliable connection points for entry, exit, and rescue. Failure during confined space work often leads to severe outcomes.

Safety Gear Connectors used here must allow:

- Smooth movement through openings

- Reliable locking under load

- Compatibility with rescue devices

Indian Inovatix supplies connectors suitable for confined space entry and retrieval systems.

Maintenance and Inspection of Safety Gear Connectors

Safety Gear Connectors require routine inspection to remain safe for use.

Inspection should check:

- Gate function and closure

- Body deformation

- Corrosion or cracks

- Markings and load rating

Indian Inovatix provides guidance on inspection intervals and replacement cycles to support long-term safety planning.

Common Errors in Using Safety Gear Connectors

Many incidents occur due to misuse rather than product failure.

Common errors include:

- Side loading connectors

- Using connectors as anchors

- Mixing incompatible components

- Using damaged connectors

Training and correct procurement reduce these risks. Indian Inovatix supports organizations with consistent connector supply to avoid mismatches.

Why Indian Inovatix for Safety Gear Connectors

Indian Inovatix designs and builds Safety Gear Connectors for industrial use. As a manufacturer, supplier, and safety systems specialist, the company supports projects from planning to execution.

Organizations trust Indian Inovatix for:

- Consistent product quality

- Certified connectors

- Bulk supply capability

- Support for EPC and infrastructure projects

Safety systems are only as strong as their connectors. Indian Inovatix ensures that strength remains reliable.

Frequently Asked Questions

What are Safety Gear Connectors used for

Safety Gear Connectors link harnesses, lanyards, lifelines, and anchors within fall protection systems.

Are Safety Gear Connectors load tested

Certified Safety Gear Connectors are tested for fall arrest loads under defined standards.

Can Safety Gear Connectors be reused

Yes, if inspection shows no damage and markings remain readable.

How often should Safety Gear Connectors be inspected

Inspection should occur before each use and during scheduled safety checks.

Are Safety Gear Connectors suitable for construction sites

Yes, when selected for load rating and environmental exposure.

Do Safety Gear Connectors differ from carabiners

Industrial Safety Gear Connectors meet higher load and gate strength requirements.

Can Safety Gear Connectors be used in confined spaces

Yes, specific connector types support confined space entry and rescue systems.

What materials are used in Safety Gear Connectors

Common materials include alloy steel and treated aluminum for strength and durability.

Are Safety Gear Connectors mandatory in fall arrest systems

Yes, they form essential load-bearing links in the system.

Where can Safety Gear Connectors be sourced in bulk

Indian Inovatix supplies Safety Gear Connectors for large industrial and infrastructure projects.

Conclusion

Safety Gear Connectors play a direct role in protecting workers in high-risk work environments. They connect safety systems, manage fall forces, and maintain continuous attachment during work at height and confined space operations.

Indian Inovatix designs and supplies Safety Gear Connectors built for industrial conditions, certified use, and project reliability. Every worker deserves safety. Equip your team with certified fall protection today. Enquire now for bulk pricing, request a quote, or customize solutions.