The performance and safety of forklifts and other material handling appliances depends on mast guide bearings. These bearings are designed to direct the movement of the mast to allow easy, accurate lifting and dropping of loads, and lessen friction and wear to the machinery. Knowledge of the various kinds of mast guide bearings, their uses and selection of a reliable supplier is a key to industrial operation, warehouse management, and equipment maintenance.

What Are Mast Guide Bearings?

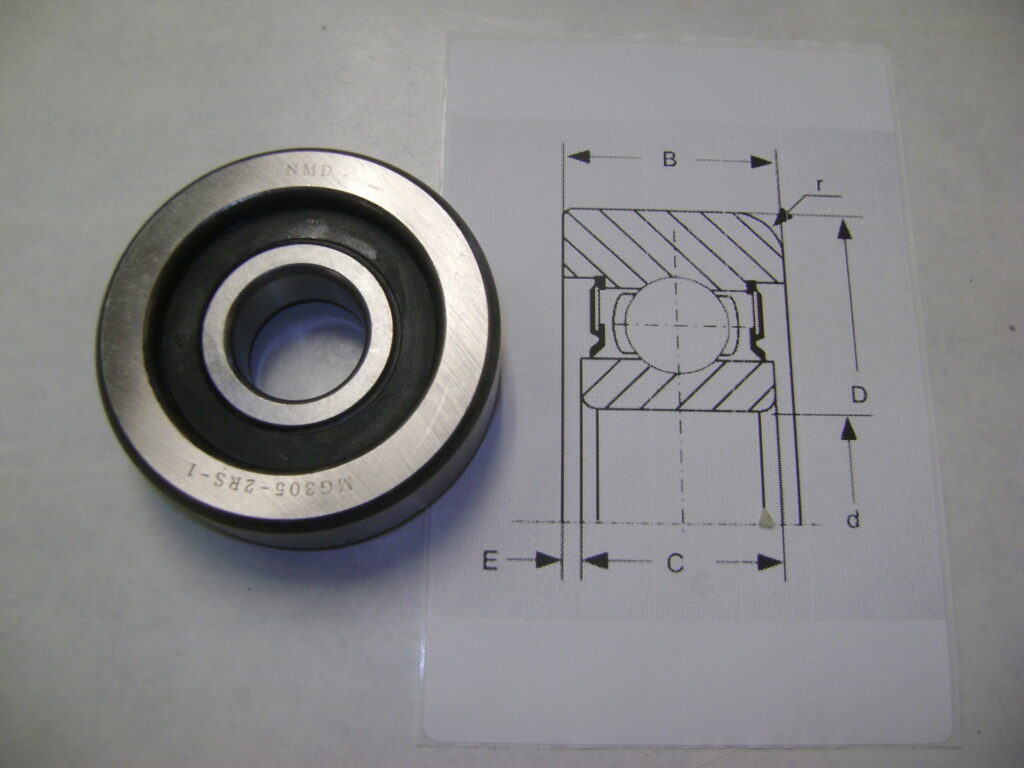

Mast guide bearing is a special piece that provides the mast of a forklift with a support to enable it remain stable and straight during lifting and lowering. These bearings also minimize friction between the mast and carriage so that it moves smoothly even when heavy loads are used. Mast guide bearings increase the life cycle of the forklift and improve its efficiency since wear and vibration are reduced.

Mast guide bearings have to be used in both small warehouse forklifts and large industrial equipment because they are vital to the equipment in terms of safety, precision and durability. Their purpose of directing the mast renders them a very important feature in avoiding imbalanced wear and tear, misalignment, or failure to operate.

Forklift Guide bearings to Masts.

Forklift mast guide bearings are specially designed to deal with the rigorous requirements of forklift business. They are made to support vertical and lateral forces, to ensure the mast is straight and does not tilt or sway in the lifting process. Good quality forklift mast guide bearings help to make the operation more smoother, minimise maintenance expenses and provide safety at workplace at both warehouse and industrial settings.

These bearings are especially significant with heavy-duty forklifts that carry heavy or dissimilar loads. Correspondingly chosen forklift mast guide bearings ensure that the channels of the mast remain wear free, ensure that the mast remains straight and minimizes the chances of mechanical failure.

Bulk Mast Guide Bearings

In the case of warehouses, manufacturing plants, and logistics companies, it may be required to source bulk mast guide bearings to have a number of forklifts or machines operating at the same time. Buying in large quantities not only brings about uniformity in performance, but it also lowers the cost of procurement and it also minimizes the downtime that is caused by replacement of parts.

Trustworthy bulk suppliers deliver bearings that are of the industrial standards and are associated with a stable quality guarantee. This is critical in the environment whereby the forklifts work 24 hours and a failure of the equipment may cause huge losses in terms of operations.

Manufacturer of Mast Guide Bearings

It is important to pick a manufacturer of trusted mast guides in order to achieve quality, durability and availability. A well-established producer of bearings can manufacture international standard bearings which are made using high grade material and subjected to strict quality control. Besides the quality of products, an excellent manufacturer provides technical assistance, timely delivery, and after-sales to a company to select the correct bearing of the particular model of forklift or equipment.

A manufacturer has to be checked based on the reputation, product variety, and his capability of providing bearings on a large scale. This will guarantee continuous supply of high quality and uniform parts to all the machinery to enhance their performance and durability.

China Mast Guide Bearings

The china mast guide bearings are popular in the world because of their competitive prices and availability. Most of the manufactures in China manufacture high quality bearings that are up to international standards providing both standard and customized solutions on forklifts and material handling equipment.

Although buying bearings in China may be economical, it is considered that the supplier should be of great quality, with hard wearable materials and correct specification. Finding a trustworthy Chinese manufacturer may be of great benefit in terms of price and supply without performance deterioration.

Mast Guide Bearing Applications

Forklifts and stackers as well as other material handling equipments require mast guide bearings. They are meant to hold the movement of the mast, keep it straight, and minimize friction. The bearings are also applicable in the industrial lift systems, warehouse automotive equipment and heavy-duty lifting equipment where precision and robustness is of vital importance.

Well-functioning mast guide bearings will increase the safety, lower the maintenance needs, and the efficiency of the lifting process microsoft 365 consulting services. With the heavy usage in logistics centers or manufacturing plants, quality bearings may be inexpensively invested in to avoid the expensive downtime and decrease the life of forklifts and other machines.

Advantages of Mast Guide Bearings of High-Quality

High-quality mast guide bearings will make the working process to be smooth and wear minimized, as well as the life of machines is prolonged. High quality bearings decrease friction, eliminate the misalignment of masts, and preserve the balance of the load. This does not only result in a better efficient operations, but also increases the safety of the operators.

Good bearing minimizes vibration and sound, as well as uneven wear on the components of forklifts. It also reduces the maintenance cost since the replacement frequency is lessened. When choosing bearings of a reputable manufacturer, a company is able to guarantee the stability of results and sustainability of its operations in material handling.

Mast guide bearing Maintenance

Maintaining the mast guide bearings is vital to ensuring the maximum operation and life of the bearings. Wear or misalignmentThis is a very important practice to be undertaken regularly through lubrication and cleaning of the keys or checking wear and misalignment. The bearings are to be examined against abnormal noise, vibration, and difficulty in moving the mast, this is likely the first signs of wear.

Maintenance is performed regularly to prevent failures of equipment, provide safety of operators and minimize downtime. Having an inspection and lubrication schedule of the mast guide bearings in an industrial setting is an investment with a great pay-off in terms of efficiency and cost saving.

Conclusion

Mast guide bearings are essential instruments in forklifts and material handling machines and they guarantee accurate and smooth motion of the mast and safety. Whether it is forklift mast guide bearings or bulk mast guide bearings, and sourcing it will be a trusted mast guide bearing manufacturer or a trusted china supplier of mast guide bearings, it is important to ensure that the right bearing is selected based on the efficiency of the operations and the long life of the equipment.

The knowledge of the types, uses, and maintenance of mast guide bearings enable the businesses to maximize performance, reduce costs, and improve the safety of operations with material handling. The high quality of bearings allows operating forklifts and industrial equipment in a stable, efficient, and reliable way, which is why mast guide bearings are an inevitable component of the modern logistics and industrial systems.