Work at height presents inherent risks that demand strict safety measures. Industries such as construction, infrastructure, energy, and industrial maintenance frequently face challenges where workers are exposed to fall hazards. Without proper protection, falls can result in severe injuries, operational delays, and compliance issues. Businesses must prioritize safety through reliable fall protection solutions.

Selecting reputable fall arrest system suppliers in India is critical. The right supplier ensures access to certified equipment, technical support, and systems tailored to your environment. Indian Inovatix stands as a trusted name among safety partners, offering engineered fall protection systems backed by industry experience and field-proven reliability.

This guide explains why quality fall arrest systems matter, how to choose a dependable supplier in India, and how these systems support compliance, worker confidence, and operational continuity.

What Is a Fall Arrest System and Why It Matters

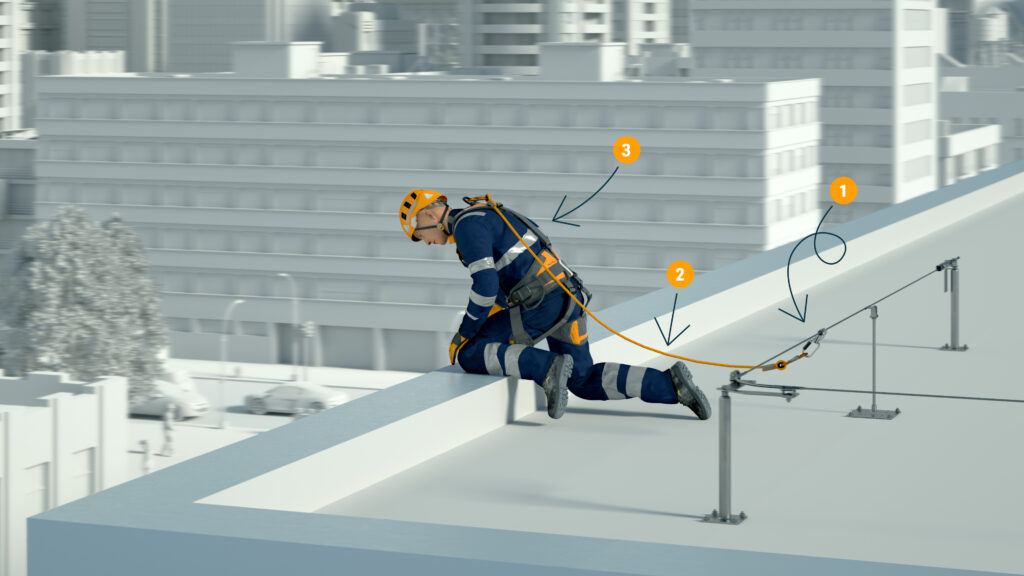

A fall arrest system is an engineered solution designed to stop a worker’s fall safely and prevent impact with the ground or obstacles. These systems are essential where employees work above a defined safe height threshold as per safety standards. A typical fall arrest system consists of:

- Anchor Points: Secure attachment points on structures

- Full Body Harness: Worn by the worker to distribute fall force

- Lanyard or Lifeline: Connects the harness to the anchor

- Shock Absorber: Reduces impact forces during a fall

Systems are rigorously tested to ensure that, when properly used and maintained, they arrest falls effectively. A fall arrest system is more than equipment. It is a reliable safeguard that maintains workforce protection, encourages confidence, and reduces liability for employers.

Core Components of a Fall Arrest System

Understanding the core components helps buyers assess quality and suitability when choosing suppliers.

Anchor Points

These are fixed or temporary structures designed to carry dynamic forces during a fall. The material and design must be compatible with the work environment.

Full Body Harness

A certified harness distributes fall forces across the torso and legs, minimizing injury risk. It should be adjustable, comfortable, and compliant with safety norms.

Lanyards and Lifelines

Lanyards connect the harness to the anchor. Lifelines provide flexible movement options for workers while remaining secured.

Shock Absorption

Shock-absorbing elements ensure that fall forces are reduced. Quality shock absorbers increase overall safety performance.

Each component must conform to regulatory standards and be supplied by manufacturers that understand industrial demands.

Why Choose Certified Fall Arrest Systems from Reputable Suppliers

Ensuring Compliance with Indian and International Safety Standards

India follows various safety regulations that align with global standards to protect workers at height. Certified suppliers provide systems that meet criteria under:

- Relevant national safety norms

- International benchmarks such as OSHA

- Industry best practices

Using certified systems reduces regulatory risk and supports compliance documentation for audits and inspections.

Consistency in Performance and Reliability

Top suppliers offer systems tested for strength, durability, and long-term use. Reliable performance is essential, especially in:

- Construction sites

- Roofing jobs

- Industrial plants

- Infrastructure projects

Substandard equipment may fail when most needed. Established suppliers carefully select products that meet stringent quality checks.

Technical Support and After-Sales Service

A supplier should offer more than products. They should provide:

- Technical guidance during system selection

- Installation support

- Inspection and maintenance guidance

- Training resources for workers

Suppliers that support customers through the life cycle of fall arrest systems help ensure ongoing safety and uptime.

Leading Fall Arrest System Suppliers in India

Indian industries have access to suppliers who specialize in personal fall arrest systems and comprehensive fall protection solutions. These suppliers typically offer:

- Personal Fall Arrest Systems

- Ladder Fall Arrest Systems

- Roof Fall Arrest Systems

- Horizontal Lifeline Systems

- Vertical Fall Arrest Systems

- Complete Fall Protection Systems

Indian Inovatix is among the reliable suppliers who combine manufacturing expertise with a distribution network across India. The company focuses on tailored solutions for industrial applications, ensuring safety and compliance.

What Sets Top Suppliers Apart

Suppliers that stand out generally share several key attributes:

- Product Certification

Suppliers partner with manufacturers whose products meet required safety certifications. - Industry Experience

A deep understanding of onsite challenges supports better product recommendations. - Custom Solutions

Not all worksites are the same. Custom-engineered systems that fit specific conditions increase safety effectiveness. - Training and Documentation

Educating end users on safe usage and maintenance enhances compliance and reduces incidents. - Nationwide Support

Availability of systems and services across multiple regions ensures quick delivery and response.

How to Evaluate a Fall Arrest System Supplier

Choosing the right supplier involves assessing several factors:

Product Range and Quality

Ensure the supplier offers a variety of fall arrest systems that suit your work conditions. Quality products should carry visible certification labels and technical specifications.

Technical Expertise

Suppliers with experienced technical teams can guide you toward proper system design and implementation. This is important for complex environments such as:

- Multi-level construction sites

- Confined spaces with fall risk

- Maintenance at heights in industrial plants

Customer Reviews and Case References

Reputable suppliers provide references from past projects. Hearing from other safety professionals confirms reliability.

After-Sales Service

Post-installation support is essential. Check if the supplier offers:

- Equipment inspection schedules

- Training workshops

- Maintenance advice

These services help maintain safety standards over long project durations.

Delivery Capabilities

Large projects may require bulk orders. Confirm that the supplier can meet delivery timelines without compromise.

Fall Arrest System Applications Across Industries

Fall arrest systems are required across various sectors where work at height is routine. These include:

Construction and Civil Engineering

Workers on scaffolds, roofs, and structures need fall protection.

Infrastructure and EPC Projects

Large-scale projects with elevated platforms demand engineered systems.

Industrial Maintenance

Plants with tanks, towers, and equipment require consistent safety measures.

Wind and Renewable Energy

Technicians working on turbines and elevated equipment benefit from lifeline systems.

Oil & Gas Facilities

Rigs and elevated walkways demand robust personal fall arrest systems.

In each sector, suppliers should match systems to project demands, considering worker movement, risk exposure, and environmental factors.

Case Example: Enhancing Safety on Industrial Projects

A large infrastructure contractor faced challenges with worker safety during elevated work. They engaged a reputable fall arrest system supplier in India to conduct a site assessment. Based on risk profiles, the supplier provided:

- Personal Fall Arrest Systems for routine maintenance teams

- Horizontal Lifeline Systems for expansive roof areas

- Ladder Fall Arrest Systems for frequent ascent and descent points

The result was:

- Improved compliance with safety documentation

- Reduced incident reports

- Better workforce confidence and task efficiency

This example shows the impact of choosing the right supplier who understands site needs and worker workflows.

Practical Tips for Implementing Fall Arrest Systems

Conduct a Worksite Risk Assessment

Before deploying systems, assess:

- Work areas with height exposure

- Frequency of tasks at height

- Worker movement patterns

- Environmental factors like wind or vibration

This ensures systems fit the actual risk profile.

Train Workers on Proper Use

Workers must understand how to use fall arrest systems, including:

- Correct harness fitting

- Attaching and detaching from anchor points

- Inspection routines before use

Training lowers misuse and prevents failures.

Regular Inspections and Maintenance

Fall arrest systems must be inspected:

- After extreme events (e.g., a fall arrest deployment)

- Periodically as per safety guidelines

- Before each use for visible wear

Suppliers often help establish inspection schedules.

Document Compliance

Keep records of:

- Fall protection plans

- Inspection reports

- Training certificates

These help during audits and reinforce accountability.

Frequently Asked Questions (FAQ)

What are the primary responsibilities of fall arrest system suppliers in India?

Suppliers provide certified systems, technical guidance, installation support, and after-sales service to ensure safe use and compliance.

How do I choose the right fall arrest system for my project?

Consider the type of work at height, environmental conditions, worker movement, and applicable safety regulations.

Are fall arrest systems mandatory in India?

For many industries where work at height is common, safety regulations require fall protection systems that comply with relevant standards.

Can fall arrest systems be custom-designed?

Yes. Reputable suppliers offer customized solutions based on specific worksite conditions and risk assessments.

How often should fall arrest systems be inspected?

Inspection frequency depends on usage, environmental conditions, and manufacturer recommendations, but a regular schedule is essential.

Do suppliers provide worker training?

Top suppliers support training programs to ensure workers know how to use and maintain fall arrest systems correctly.

What industries benefit most from fall arrest systems?

Construction, infrastructure, industrial maintenance, oil & gas, and renewable energy sectors commonly require fall protection.

What is a horizontal lifeline system?

A horizontal lifeline system allows workers to move across a work area while staying securely connected to a safety line.

Can fall arrest systems reduce liability?

Yes. Certified systems that meet safety standards help organizations demonstrate compliance and reduce risk exposure.

Do suppliers offer bulk pricing?

Many suppliers provide bulk order options with pricing that reflects project scale and system customization.

Conclusion: Choose the Right Fall Arrest System Supplier in India

Work at height should never compromise safety. Partnering with reputable fall arrest system suppliers in India ensures that your organization receives certified equipment, expert guidance, and support tailored to industrial needs. A reliable supplier is more than a vendor. They are a partner in maintaining workplace safety, supporting compliance, and protecting your workforce.

Indian Inovatix is a trusted supplier that delivers engineered fall protection systems across industries. Our solutions are designed to meet industrial challenges, provide peace of mind, and support safe, productive operations.

Safety begins with the right systems and the right partner. Contact us today to request a quote, discuss bulk pricing, or plan a customized fall protection solution for your project.